Metal Processing Capabilities & Services

What kind of 'in-house' metals processing does Arbor Metals TM offer?

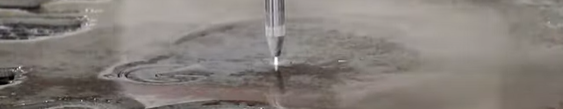

Arbor Metals TM has extensive in-house processing capabilities. Our metal processing capabilities include hi-def plasma cutting up to 4-1/2" thick and water jet cutting on our dual pump water jet up to 8" thick stainless steel plate. We shear plate up to 3/8" thick, saw cut up to 24" bar, and chamfer up to 4" pipe and tube all in-house.

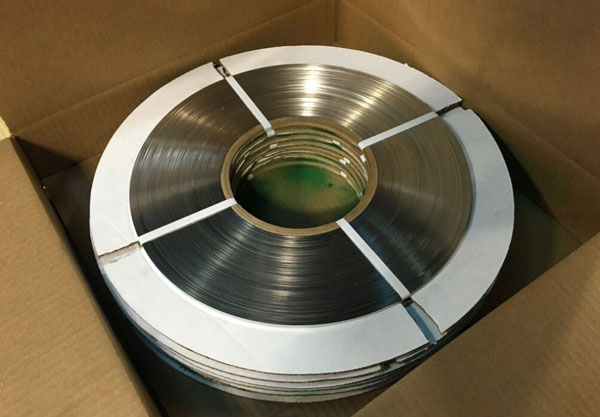

A traditional Pancake or Ribbon Wound coil consists of a single steel strip that is wound on top of itself, similar…

Oscillate (or Traverse) wound coils take pancake coils, which are welded together, and wind the slit strip back…

Slitting coil in its most basic form is taking a wider (Master) coil, pulling the master coil through slitting…

Edge Conditioning is forming the edges of strip to a desired shape beyond the standard slit edge, which is typically…

At Arbor Metals TM, we specialize in spiral wound gasket strip.

Arbor/Metals Inc offers an extensive inventory of Stainless Steel & Nickel Alloy Gasket Strip.

Industrial banding is used for multiple applications, and predominantly for use in the petrochemical, refining…

High definition (hi-def) plasma burning involves sending gas (argon, nitrogen or other combination of gases) from…

Arbor Metals TM uses the latest CNC Controlled TechniJet Water Jet Cutting Machines to process your…

Arbor Metals Inc. has the capacity to shear 3/8" x 120" Stainless Steel in-house. If your project requires a…

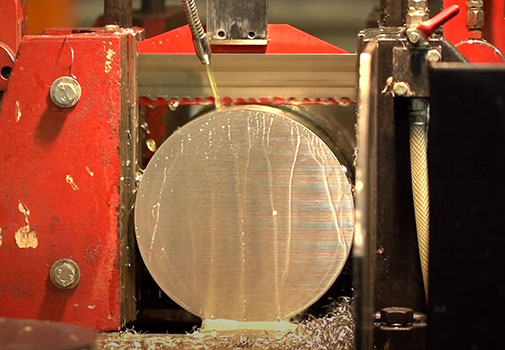

Metal Band Saws are saws that use a tensioned saw blade to cut through non-ferrous metals with tight tolerances.

Arbor Metals Inc. has the capacity to shear 3/8" x 120" Stainless Steel in-house. If your project requires a…

Arbor Metals Inc. has the capacity to roll alloys begining at .135” x 10’ width with 4-roll plate rolls, and…

Tulsa Processing Facility

In addition to our in-house processing, we have outside sources who laser cut and press brake. We also partner with additional 'next stage' processing and fabricating suppliers - delivering a complex range of services, including cylinder rolling, forming, welding, and more.

What is Precision Slit Coil?

Slitting coil in its most basic form is taking a wider master coil, pulling the master coil through slitting knives, and creating multiple narrower widths and smaller coils. At Arbor Metals TM Dallas, Texas Branch, we specialize in manufacturing precision slit coil. With 14 slitting machines in-house, Arbor Metals TM Dallas has the capability to slit coils from .003" to .125" thick, and widths from .078" to 48" wide.

Arbor Metals TM Dallas stocks and ships both non-ferrous and ferrous Metals. Our unique and highly specialized equipment allows us to provide precision slit coil to clients all over North and South America as well as to Europe, Asia, and the Middle East. Our products are used in a variety of applications, including automotive, building products, conveyor belts, defense, energy, gasket, general fabrication, heat exchanger, industrial banding, industrial filtration, medical, petrochemical, as well as in a variety of other industries.

Our Team

Our Production team has an average tenure of 20 years with the company. Manufacturing in the Precision Slit Coil market requires highly trained, experienced associates. Our team consists of individuals who are 'more than machine operators.' They are Artisans in their craft. The Sales Team has extensive experience and knowledge gained over an average of 25 years in the slitting industry. Our Customer Service team is ready to assist with any questions regarding shipping dates, invoices, quality issues, Mill Test Report requests, or any other situation where you need assistance. They have over 20+ years of experience as well.

Arbor Metals TM is here to provide you with experienced, knowledgeable, technical resources to ensure we meet your material requirements and specifications.